|

Product Details:

Payment & Shipping Terms:

|

| Name: | Copper Tungsten Alloy Parts | Model Number: | W75Cu25, W70Cu30, W80Cu20, W90Cu10 |

|---|---|---|---|

| Shape: | Rod, Sheet, Rod, Sheet,ring, Customized | Application: | Industry,electrics |

| Dimensions: | Dia 1-80mm | Length: | <=300mm |

| High Light: | W75Cu25 Tungsten Copper Alloy,195HB Tungsten Copper Alloy,W75Cu25 High Voltage Discharge Electrodes |

||

W75Cu25 Tungsten Copper Alloy Parts As High Voltage Discharge Electrodes With Hardness 195HB

Tungsten Copper Alloy types,chemical compositions and main properties:

| Grade | Density: g/cm3 | Tensile Strength/Mpa | Hardness (HB) | Conductivity %IACS | Main Applications | |

| Room Temperature | 1600℃ | |||||

| WCu7 | 17.3~17.8 | 400~750 | 50~120 | 280 | ≥26 | Nozzle, gas rudder |

| WCu10 | 16.8~17.3 | 400~700 | 60~100 | 260 | ≥27 | Nozzle, gas rudder |

| WCu15 | 16.0~16.5 | 300~600 | / | 240 | ≥30 | component, barium salt electronic cathode |

| WCu20 | 15.1~15.5 | / | / | 220 | ≥34 | Contact, electrode |

| WCu30 | 13.7~14.2 | / | / | 175 | ≥42 | Contact, electrode |

| WCu40 | 12.7~13.2 | / | / | 140 | ≥47 | Contact, electrode |

| WCu50 | 11.7~12.2 | / | / | 115 | ≥55 | Contact, electrode |

Tungsten Copper alloy Properties:

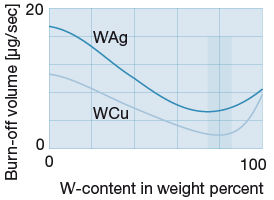

Tungsten copper alloy is a composite metal of tungsten and copper, which combines many excellent characteristics of tungsten and copper. Among them, tungsten has high melting point (tungsten melting point is 3410 ℃, copper melting point is 1083 ℃) and high density (tungsten density is 19.34g/cm3, copper density is 8.92g/cm3); Copper has excellent electrical and thermal conductivity. Tungsten copper alloy (composition generally ranges from wcu7 to wcu50) has uniform microstructure, high temperature resistance, high strength, arc erosion resistance and high density; With moderate conductivity and thermal conductivity, it is widely used as military high-temperature resistant materials, electrical alloys for high-voltage switches, EDM electrodes and microelectronic materials. As parts and components, tungsten copper alloy is widely used in aerospace, aviation, electronics, electric power, metallurgy, machinery, sports equipment and other industries.

No arc erosion: With the right mix of materials.

|

|

![]()

We also offer tungsten copper alloy rings, plates, spare parts, etc..

Contact Person: Lisa Ma

Tel: 86-15036139126

Fax: 86-371-66364729